Article for the Week:

Lean Mfg focuses on waste elimination and most professionals are aware of the 7 types of wastes in any mfg unit.

OverProcessing is one of the wastes and it is little difficult to identify, because it looks like Work. This post helps in identifying OverProcessing waste.

OverProcessing are the efforts / activities we do to compensate for some of our inefficiencies in the processes. In these cases, we process more than the customer's requirement.

Some examples of OverProcessing:

Multiple stages of Inspection (between departments / sections),

Multiple Counting(between processes / stages)

Redundant documentation - same data entered in ERP, Excel Sheets and Registers

Multiple packing and unpacking of materials between stages

Multiple Authorizations (which leads to delay in output)

Excess application of consumables and then removing them later (Grease, Oils)

Tightening the nuts in one station and loosening the same in the subsequent stations for some other activities

Applying Polythene covers for shiny portions in the product - to prevent scratches and remove the covers later during packing

Applying “OK” Stickers after quality check - This is only for our internal identification

Activities done to monitor the excess inventory - Applying Rust Prevention Oil, Using a manpower to monitor / track WIP, Entering the data in a system, etc.

All the above activities are some of the examples for OverProcessing.

Do you find these OverProcessing wastes in your unit? Please share your comments.

2 Quotes for the Week:

"A leader takes people where they want to go. A great leader takes people where they don't necessarily want to go, but ought to be." —Rosalynn Carter

"Leaders think and talk about the solutions. Followers think and talk about the problems." —Brian Tracy

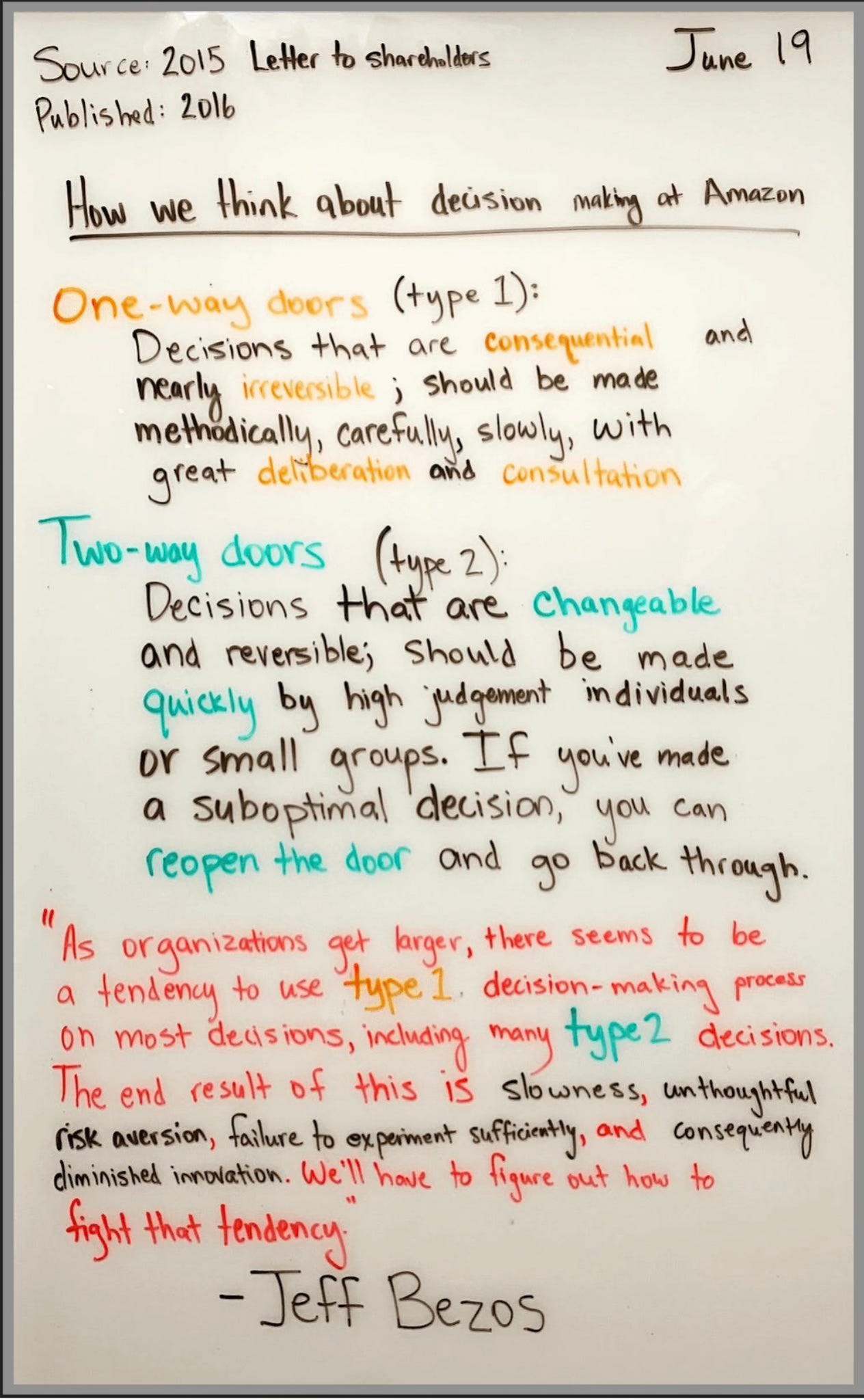

1 Image for the Week:

From Jeff Bezos’ Letter to Shareholders - 2015