How to Implement 2 Bin System

+ 2 Quotes and 1 Image to kindle your thoughts

1 Article for the Week:

In the fast-paced world of business, efficient inventory management is crucial for improving productivity and optimizing costs. One simple and effective method proven to streamline inventory processes, particularly for Low Value and Low Consumption (Class C components), is the Two-Bin System.

This system would help the team focus more on “A” and “B” Category items, by reducing the focus on “C” Category items (because, we do not want to spend too much energy and time for “C” Category items)

How Does the Two-Bin System Work?

Setup: Each inventory item is split into two separate bins.

Primary Bin: This bin holds the stock that is be actively being used.

Secondary Bin: This bin holds the reserve stock of the same item

Replenishment: When the primary bin is empty or reaches a minimum level, it's replenished using the stock from the secondary bin.

Ordering: As soon as the secondary bin is used to refill the primary bin, an order is placed to replenish the secondary bin itself.

Implementing the Two-Bin System:

Assess Inventory Needs: Identify which items are critical and would benefit most from the Two-Bin System, based on usage frequencies

Determine Bin Sizes: Calculate the optimal size for each bin based on usage rates and lead time for replenishment, and storage capacity

Label Bins: Clearly label each bin as either primary or secondary to avoid confusion.

Set Reorder Points: Establish reorder points based on the consumption rate and lead time to ensure timely replenishment.

Training: Educate your team on the process to ensure smooth implementation.

Benefits of the Two-Bin System

Continuous Availability: Ensures that you never run out of “C” Category Items

Reduces Overstocking: Helps in maintaining optimal inventory levels and reduce Non-Moving Stock

Cost-Effective: Minimizes storage costs by preventing overstocking

Are you following these practices in your company?. Please share in the comments.

2 Quotes for the week:

1. “Progress cannot be generated when we are satisfied with existing situations.” -Taiichi Ohno

2. “Measurement is the first step that leads to control and eventually to improvement. If you can’t measure something, you can’t understand it. If you can’t understand it, you can’t control it. If you can’t control it, you can’t improve it.” - H. James Harrington

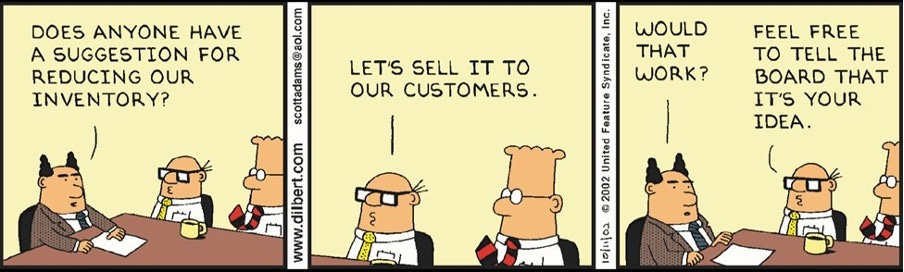

1 Image for the week: